Premiere Finishing & Coating

Custom Finishing

To Your Specifications

Now more than ever, if you can dream it, we can finish it! Our state-of-the-art finishing plant can assist you with any color and finish on any substrate.

Want updates?

Premiere Finishing & Coating

Let us take care of

the Finishing for you!

- Custom Finishing

- Toll Finishing

- Flexible capacity

- Private Label Programs

Spray and Panel Line

After twenty-one years of providing custom floor finishing services, flex capacity, and turnkey solutions to the hardwood flooring industry, Premiere Finishing & Coating has expanded its capabilities in a significant way by installing two new production lines with enhanced finishing capacity for cabinetry, doors, frames, moldings, panels, and other millwork.

Dream it

The UV Panel Line has 6 roll coaters, a filler machine, Miltec UV lamps, denibbers, and an in-line sealer sander. It can finish clear, stained, opaque, and primed, whatever color and finish is required.

Finish it

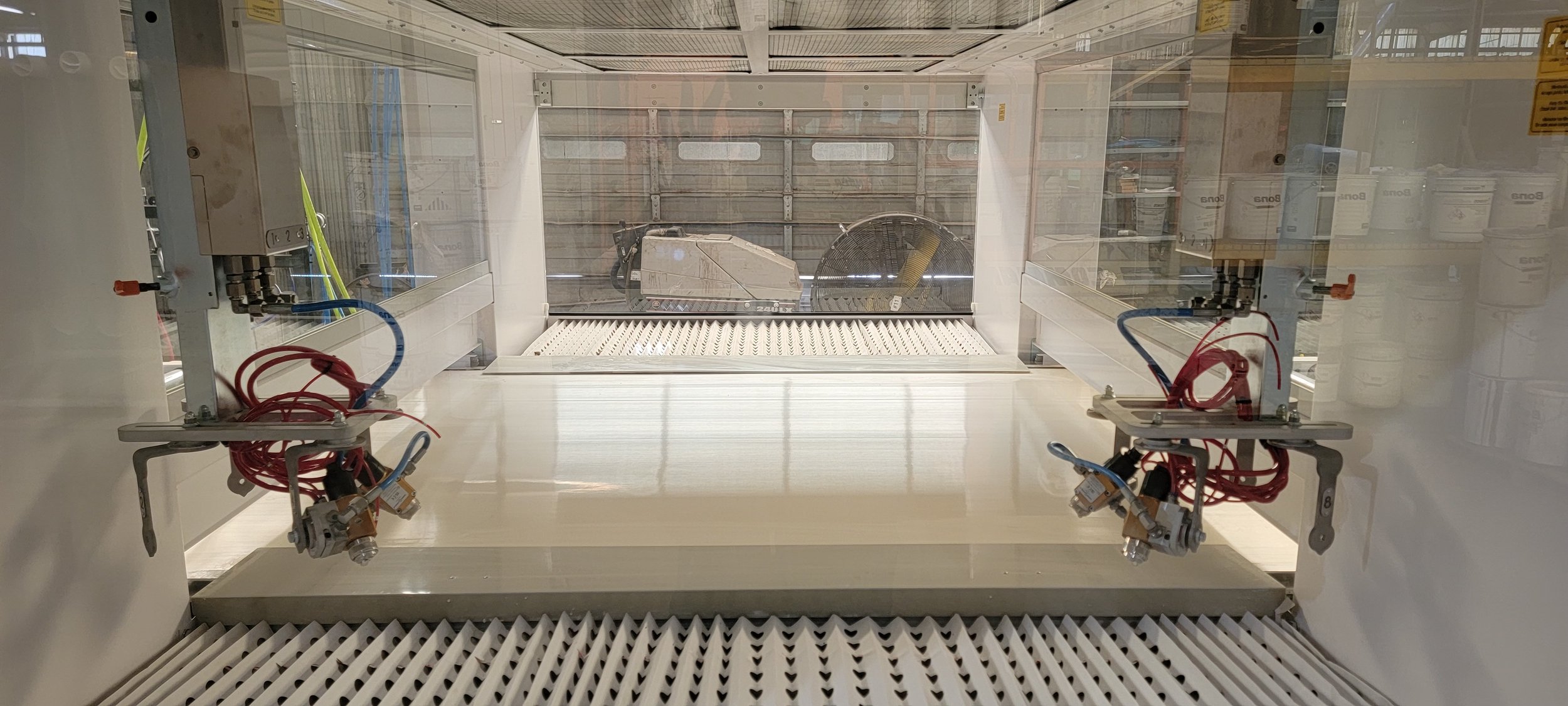

The new Makor reciprocating Spray Line / Oven combination can handle just about anything we throw at it – cabinet parts, doors, frames, moldings, panels, and anything that doesn’t fit on the Flat Line. It is versatile and perfect for any 3D spray requirement, large or small.

Spray and

Panel Line

After twenty-one years of providing custom floor finishing services, flex capacity, and turnkey solutions to the hardwood flooring industry, Premiere Finishing & Coating has expanded its capabilities in a significant way by installing two new production lines with enhanced finishing capacity for cabinetry, doors, frames, moldings, panels, and other millwork.

Dream it

The UV Panel Line has 6 roll coaters, a filler machine, Miltec UV lamps, denibbers, and an in-line sealer sander. It can finish clear, stained, opaque, and primed, whatever color and finish is required.

Finish it

The new Makor reciprocating Spray Line / Oven combination can handle just about anything we throw at it – cabinet parts, doors, frames, moldings, panels, and anything that doesn’t fit on the Flat Line. It is versatile and perfect for any 3D spray requirement, large or small.